Summarize

- Cooler air improves the brightness and durability of LED lights

- High temperatures reduce the light output and lifetime of LED lights

- The junction temperature has a significant impact on the performance of LED lights

- Aluminium improves thermal management and durability of LED lights

- Cold environment extends LED lifetime and improves light output

Believe it or not, cooler air can make LED lights burn brighter and last longer, while a hot environment will shorten the life of the LED. Why can’t LED withstand heat? In this article, we will explore the topic of why the temperature of the installation site affects LED lights.

Why do LED lights like when it’s cold?

In general, high temperatures reduce the ability of the LED to produce light. The heat, together with higher voltage, heats the semiconductor. The more powerful the LED, the higher the heat load and the better the cooling of the LED needs to be.

“In general, the cooler the environment, the higher an LED”™s light output will be. Higher temperatures generally reduce light output. In warmer environments and at higher currents, the temperature of the semiconducting element increases”-National Lighting Product Information Program

What is the junction temperature of a LED and what is the meaning of it?

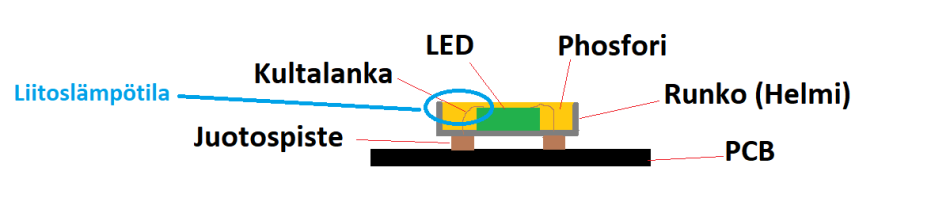

The temperature of the junction between the LED chip and the substrate is called the junction temperature. This connection point usually has the highest temperature of the appliance, so its value is suitable to indicate the heat output. The picture below shows the structure of a LED strip when viewed from the side. Below is the PCB-base itself, to which the LEDs are attached to.

Today’s LED luminaires are designed with thermally conductive materials, to transfer the heat away from the junction point onto the soldering point. The solder point is at the interface between the LED package and the printed circuit board and/or separate heat sink. The efficiency of the internal thermal pathways is reflected in the internal thermal resistance of the LED. The lower the internal temperature, the better the quality of the LED is in thermal terms.

The maximum junction temperature is set by the LED circuit manufacturer and the product design should take into account the heat generated by the LED circuit and how to conduct it away. LEDs vary widely in design, as they can be used for a wide range of lighting applications.

What do high temperatures do to LED lights?

Temperature has a tangible effect on the material and luminous intensity of LED light. If I had to say something briefly, it’s that the temperature of a LED has a big impact on its lifetime and light output. Much research has been done on the matter. For example, this study investigated the effect of different materials on the thermal conductivity of LEDs and proved the temperature is a primary determinate for long-term reliability. Here is another study on the subject.

Inexpensive LED lamps are often made of plastic which is poor at conducting heat away. Therefore, plastic LED lights are rarely durable.

Led can’t withstand heat, cold is good.

Led lights operate at 100% efficiency when the junction temperature – the temperature inside the LED circuit where the electrical energy passes through – is 77 degrees Celsius.

When the temperature rises by about 20 degrees Celsius, the calculated lifetime of the LED is halved and again, at 20 degrees it is halved from the previous.

So if the starting assumption is 77 degrees and the led lasts 50000 hours, then 97 degrees means 25000 hours and 117 degrees means only 12500 hours!

This is why a 30g LED bulb will not last as long as a well-designed LED lamp with 200g of aluminium conducting heat away from the LED circuit.

The ambient temperature of the LED luminaire directly affects the junction temperature. Other things that affect the junction temperature are the electrical current and the amount of the material that conducts the heat away from the LED, the heat sink. Both LED luminaires and LED strip lights require aluminium.

A cooling element is usually a material in or around the heat source, often metal, that cools by conducting and drawing heat away from sensitive LED circuits. Aluminium is an excellent choice for this.

In other words: Always make sure that the LED lamp you buy is heavy. The more there is of thermally conductive materials, the cooler the LED circuit and the longer the lifetime.

The effects of hot and cold on LED lights

The low thermal stress of a cold environment puts less strain on the diodes and the controller. Studies have shown that when LED lights are installed in cold environment, their degradation rate is reduced and their light output is improved. So, conversely, in a hot, humid environment, the life of an LED light is shortened and its light output is reduced.

“Results showed the dominant failure mode to be solder joint failure. When the delta temperature increased, the system failed in a shorter time and showed faster lumen depreciation” -National Lighting Product Information

The researchers found that prolonged heat can significantly shorten the life of many LED luminaires. Higher ambient temperatures lead to higher junction temperatures, which can increase the degradation rate of the LED junction. In this case, the light output of the LED may decrease irreversibly and more quickly in the long term than at lower temperatures.

L70 life cycle test

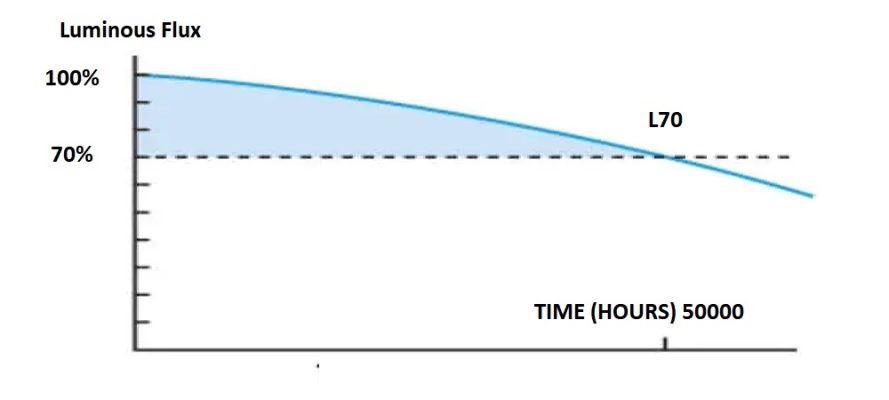

The technical term “luminuous flux reduction” refers to how much the luminous intensity of LED lights decreases over time. When the light output is 70% of the original value, the LED bulb is usually replaced. This 70% value is in fact the industry standard term – L70.

The previously mentioned 77 degrees Celsius is the most commonly used temperature for measuring the L70 arc of a bulb.

Lastly

Continued exposure to high temperatures can contribute to a loss of luminous intensity and thus reduce the lifetime of the LED lamp. Most experts mostly agree that high themeratures are the biggest threat to LED lights.

In cold environments, it is worth considering LED lighting solutions, not only for energy saving reasons, but also for better light output and longer than normal lifetime. Those working in hot environments, on the other hand, should think long and hard about the thermal management of a building – if not for human well-being, which should be reason enough, then for the economic benefits of proper LED lighting.

Led lighting expert

LedStore has been an expert in led lighting since 2010.

We have our own product design, so our products are technologically state-of-the-art.

We focus on light colour temperature controlled and high colour rendering index lights.

We do around

500 lighting designs in a year.

We offer a service of custom made led strips, i.e. custom made led light strips in profile.

Also installed.

Remember that we are always ready to offer our help to you along the way, by email (myynti@ledstore.fi) and by phone (045 251 4510).

As always, feel free to share photos of your own projects on social media at ledstore.fi at Instagram and ledstore.fi at Meta.

We love to see the cool things done by our LEDs, and it also helps to provide inspiration for those who are not sure about the power and awesomeness of LEDs.

Did you know that we already have over 3500 pictures of our LED installations in our Gallery!

Led Lights Gallery:

Product gallery: Pictures of products in different installation locations

Indirect light: Indirect light in different spaces

Room-specific: Light in different rooms

References: Complete houses that have been photographed