Summarize

- LED strips typically have a lifetime of 50 000-80 000 hours

- Service life is affected by temperature, method of use and product quality

- High-quality components and power supply extend the life of LED strips

- The L70 meter determines when the LED dims to 70% of its original luminous intensity

- Heat and poor quality components can shorten the life of LED strips

One of the main advantages of LED strips is their very long lifetime. But how long does the led tape actually last? How is lifetime defined? LED strip lights typically have a lifetime of 50 000-80 000 hours, which is a very long time. However, the lifetime of a LED strip depends on a number of factors, such as temperature, application and product quality.

Factors affecting the lifetime of the LED strip

- Component quality: High quality LED chips, driver circuits and other components can extend the lifetime of the led strip.

- Operating temperature: Overheating can significantly reduce the lifetime of the LED strip lights.

- Use: The frequency and duration of use can also play a role in the lifetime of the LED strips.

- Power supply: The quality and stability of the power supply can affect the lifetime of LED strips.

- Voltage fluctuations: Sudden voltage spikes and drops can damage the LED strip and shorten its lifetime.

- Environmental factors: Exposure to moisture, dust and other environmental factors can shorten the lifetime of the LED strip.

Led strip structure

The main components of a traditional LED strips are LEDs, FPCBs (Flexible Printed Circuit Boards), resistors or other components. LED strips are manufactured using the SMT (Surface Mount Technology) assembly process, where LEDs, resistors and other components are attached to the FPCB.

However, alongside this SMD structure, there is now a newer COB technology, of which we have written an article. Among other things, it solves the problem of breakage thanks to its greater flexibility.

Some outdoor LED strips are wrapped with silicone or PU glue.

Please note that LED strips with a high IP rating have a shorter lifetime than IP20 LED strips, because LED strips with a high IP rating cannot dissipate heat equally well. The cooler the environment, the greater the light output and the lifetime of the LED will be. Higher temperatures tend to reduce the light output and the lifetime of the LED. In other words, the temperature affects how long the LED strip lasts. Read here, How does heat affect LEDs?

The most critical component of the LED strip is the LED circuit. The lifetime of the circuit essentially determines the lifetime of the LED strip. How then do you calculate the lifetime of LEDs?

LED lifetime and the 70% rule (L70).

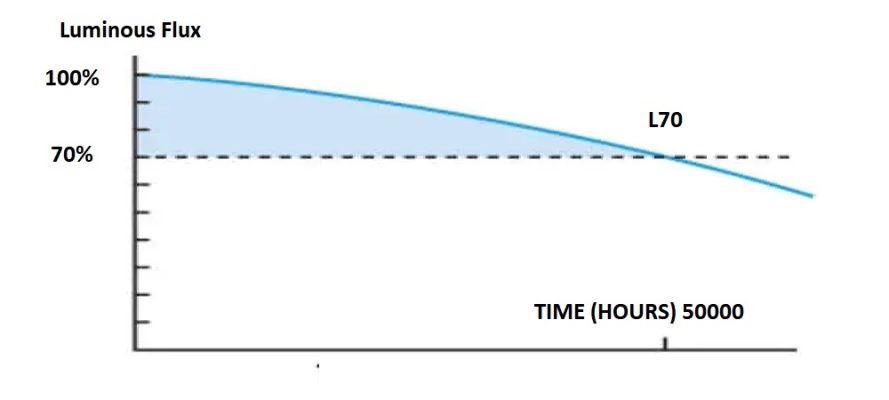

Unlike incandescent bulbs, which burn out, and fluorescent tubes, which start to flicker, LEDs behave differently over time, slowly and gradually losing their light output. Unless it is a “catastrophic” failure caused by a power surge or mechanical damage, you can assume that the LEDs in the LED strip will work until they are too dim to use.

But what does “too dim to use” mean? Different lighting applications have different answers. However, the industry has decided, somewhat arbitrarily, that 30% light loss or the remaining 70% of light is the standard. This is often called the L70 metric, and is defined as the number of hours it takes for an LED to dim to 70% of its original luminous intensity.

How is L70 calculated?

Because the choice of material used to manufacture LEDs varies widely between different types and manufacturers, the LM-80 test method was developed as the primary standard for testing light lifetime. According to the LM80, the sample is tested at 55 and 85 degrees Celsius, as well as at the temperature and current selected by the manufacturer. The time interval for measuring the change in luminous intensity is typically 6000 hours.

LM-80 testing is usually carried out in a third-party laboratory to ensure objective results, and the results are published in a report.

The difficulty of testing the lifetime of LED lights is that it takes a lot of time. Even with the LED lights are on 24/7, the 6 000-hour test takes 250 days. This is an eternity for fast-changing industries like LED lighting. Testing a product to the full 50 000 hour requirement, on the other hand, requires almost six years of continuous testing.

For this purpose, the TM-21 extrapolation algorithm is used. The algorithm takes into account the performance of the LM80 sample for the first few thousand hours and gives an estimated lifetime. LM80 test reports usually give out the lifetime of the L70.

The matter is complicated, which is why CREE, one of the world’s largest manufacturers of LED circuits, has made a video about it:

Things that most affect the lifetime of led strips

Heat

As mentioned above, heat significantly reduces the lifetime of LEDs. Aluminium is an excellent heat dissipating metal, which significantly extends the life of LED strip. It is therefore advisable to install the LED strips in a well ventilated place, and to fix them to a heat conductive material.

Double-sided tape

LedStore uses 3M branded thermal tape. However, many suppliers offer anonymous or, even worse, fake labels. Poor tape does a poor job of conducting heat away from LED strip and even acts as an insulator between the LED and the aluminium, increasing the heat load of the LED strip. One key to a long-lasting permanent installation and thermal conductivity is good quality tape.

Components

Resistors are used to regulate the forward current flowing through the LEDs so that they operate at their designed power. The value of a resistor can change from one batch to another. Poor quality resistors and other components can shorten the lifetime of a LED strip or even damage the strip. So the quality of the components will affect how long LED strip lasts.

Power supply

The power supply is also an important part of the big picture and affects the duration of the strip. It is therefore advisable to use a high-quality, certified power supply. A poor quality power supply can give an unstable voltage that can be higher than the operating voltage of the LED strip. This will damage the LED strip or shorten the lifetime of the LED strip.

Also make sure that the power required by the LED strip does not exceed the maximum rated capacity of the power supply. This ensures that the transformer for the LED strip will last a long time and keep a stable current for the LED strip. The power of the LED strip should not exceed 85% of the maximum rated capacity of the power supply.

FPCB (flexible printed circuit board)

High-quality, 3-4 oz double-layer, pure copper, flexible circuit boards ensure a significant current flow, reduce heat build-up and help heat dissipate faster. Excessive heat will shorten the life of the LED, so a thick copper base will help the LED last longer.

Conclusion

Led strips can have a lifetime of up to 80 000 hours. The quality of raw materials such as LEDs, the quality of the LED stripbase material and resistors, waste heat management and the quality of the power supply all affect the actual lifetime of a LED strip and thus determine how long the LED strip will last.

Led lighting expert

LedStore has been an expert in led lighting since 2010.

We have our own product design, so our products are technologically state-of-the-art.

We focus on light colour temperature controlled and high colour rendering index lights.

We do around

500 lighting designs in a year.

We offer a service of custom made led strips, i.e. custom made led light strips in profile.

Also installed.

Remember that we are always ready to offer our help to you along the way, by email (myynti@ledstore.fi) and by phone (045 251 4510).

As always, feel free to share photos of your own projects on social media at ledstore.fi at Instagram and ledstore.fi at Meta.

We love to see the cool things done by our LEDs, and it also helps to provide inspiration for those who are not sure about the power and awesomeness of LEDs.

Did you know that we already have over 3500 pictures of our LED installations in our Gallery!

Led Lights Gallery:

Product gallery: Pictures of products in different installation locations

Indirect light: Indirect light in different spaces

Room-specific: Light in different rooms

References: Complete houses that have been photographed