Summarize

- Flickering LED strip may be caused by poor connections or parts

- Visible flicker below 100 Hz, invisible above 100 Hz

- An overloaded power supply can cause the LED strip to flash

- Wireless control pairing mode may cause flicker

- Faulty LED strip can be the cause of flickering

The flickering LED strip is a nuisance that needs to be fixed. There are different reasons for flickering light, at different levels. Some of the flicker is visible and distracting to the eye, while some is only visible through the camera lens. In this article, we will go through the different types of flicker.

What are the different types of flicker and what causes them?

The rapid on/off cycle of a light source is called flicker. Intentional flashing in a club or at a concert is part of the visual experience, but at home the unintentional “strobe effect” is annoying.

There are actually two types of flicker: visible and invisible. If the flicker frequency is below 100 Hz, it will cause a visible flicker (i.e. the light will switch on and off up to 100 times per second). Flicker invisible to the eye occurs at frequencies above 100 Hz. It is typically visible through the lens of a camera, for example. People react differently to this “invisible” flicker, but it can cause a variety of adverse effects, including headaches, migraines, dizziness and eye strain. For epileptics, the flash can provoke a seizure.

Flicker can be caused by

- poor connections,

- incompatible parts,

- overloaded or faulty voltage source,

- led-ribbon transformer, which is for creating wireless control in pairing mode,

- or a faulty LED strip.

We will now look at these separately:

1. Poor connections

The flicker that occurs after plugging in is visible to the eye if the connections are poor. The primary cause of flicker is insufficient or loose connections. They can interfere with and occasionally connect to electricity. Poor joints usually occur with unsoldered connections. Good soldered joints reduce the risk of a bad joint. Also the connections drivere.g. using the screw connectors may become loose.

To find out if there is a soldering problem on the low-current side, you can press the unsoldered connector with your finger. If the connection is the cause of the flicker, the LED strip will flicker, the flicker will change or the light will go out. If this happens with a soldered joint, the way to fix it is to reheat the broken joint, i.e. re-solder it.

2. Incompatible parts

Usually, flicker stripLED stripoccurs when the LED stripis dimmed. If this is the case, first make sure that the LED stripand the driver are compatible with the dimming. If you have a wireless controller, make sure that the controller and dimmer protocols are compatible. For example, a DALI dimming controller and a 0-10V dimmer are not compatible. In the picture below, a TRIAC dimmer is connected to the push-dim and PWM driver. Dimming will definitely not work with this combination.

3. Overloaded or faulty power supply

One of the most common causes of flickering LED stripis overloading of the LED driver (power supply, driver). High quality led drivers usually have overload protection. Led transformer switches on and off in case of overload. The LED stripare then alternately on and off, giving the impression that they are flickering. Led tape can also flicker as a result of a bad or incorrectly powered led transformer. To avoid overloading problems, the DC power supply (VDC) should be selected leaving a margin of about 15% for the maximum load. We have written more about choosing an LED driverin our article: Choose the right power supply for your LED strip.

4. Transformer in pairing mode for wireless control

If a Zigbee protocol driver used for smart control flickers as soon as it is first connected to power, this is due to the activation of the pairing mode. Zigbee transformers plug into pairing mode, making it easy to connect a wireless controller, or pair with a bridge/hub. The pairing mode lasts for three minutes, after which the lights remain steady if they cannot find a pair. We’ve written more about pairing in our article Zigbee lighting control part 5, for example.

5. The flashing LED strip is faulty

The flashing LED strip may be faulty. Led stripare tested at the factory, but incorrect handling when unpacking or installing stripis possible. If the LED strip is twisted or folded too much, or just at the LED chip, for example, problems may occur, either immediately or after a period of time as the strip warms up and cools down several times. The same can happen at the connection points of the led strips, where the led strip is connected to the next strip by soldering.

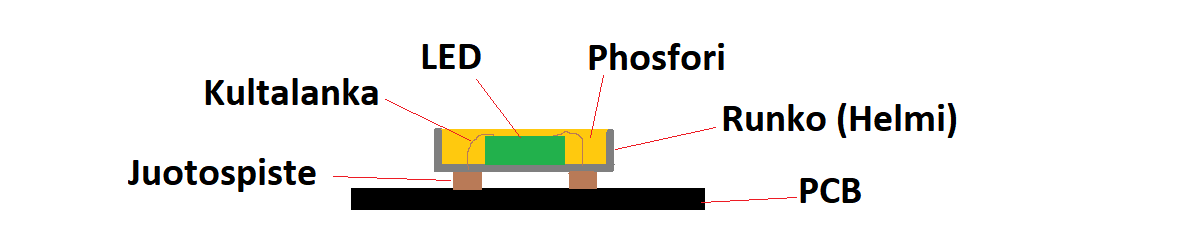

The LED chip and its holder are typically the cause of the problem. The LED chip is the component that produces the light, and a gold wire connects the LED chip to the LED holder. Electricity can sometimes flow and sometimes not, when the LED chip and holder are not connected properly, causing the LED to flash. When you notice that a particular part of the LED stripis flashing, press this part of the LED with your finger. The flicker may change or disappear. This way you have located the failed point.

Compared to SMDs, COBs do not have gold wires and the problem of breakage is lower. If you want to learn more about the difference between led strips read our blog article What is the difference between SMD and COB led strip.

Invisible flicker stripLED strip

Maybe you see some lines in your smartphone’s camera images and notice some flicker in moving objects? This is a phenomenon called invisible flicker.

AC 230V led ribbon

Because alternating current (AC) is used to carry most of the world’s electricity, electric lights flicker. An alternating current is a kind of electric current that changes direction 50-60 times a second, depending on where in the world you live. Typically, this is represented by a sine wave. Direct current (DC), on the other hand, is continuous and only flows in one direction.

Anything connected to AC power loses power momentarily when the current changes direction. So all the lights are practically flickering, because electricity is always flowing back and forth. What kind of glare a person finds disturbing depends on his or her personal characteristics.

PWM dimmers

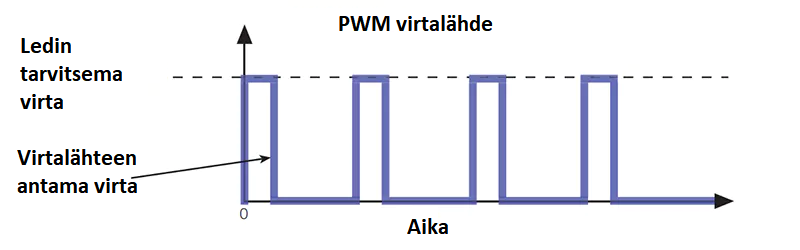

Dimming the PWM signal produces an invisible or sometimes even visible flicker.

PWM is the deliberate alternation of on and off modes of a DC power supply. PWM is used to simulate different brightnesses by adjusting the time between on and off modes. If the LED is at 0% brightness half the time (off) and 100% brightness half the time, it will give the impression of 50% brightness (on).

Because flicker is invisible, it typically does not cause problems. However, these imperceptible flickers are a disaster when recording video. The fact that the FPS (frames per second) recording of the camera is not in line with the frequency of the electricity causes the flicker in the video to become more noticeable and visible. It is called the “stroboscopic effect”.

To achieve the desired effect, almost all “colour changing” controllers (CCT or RGB) and LED strip dimmers use PWM dimming. Unfortunately, many PWM dimmers use frequencies that are too low. To eliminate the effects of PWM flicker on the LED driver, the frequency should be above 600 Hz or higher. However, most PWM dimmers do not have a PWM frequency specification, which often means that they operate at a frequency of a few hundred hertz.

For more information on LED strip dimming, see our blog article How to dim stripstrip lighting.

How to stop LED strip flickering?

Don’t worry, once the problem is located, something can be done about it. Here we go through the different ways to fix LED stripflicker.

How to fix a VISIBLE LED stripflickering?

- First, make sure that all connections – including cables, connectors and LED transformers – are safe. Poor connections can produce excessive resistance, overheat and even start a fire. As a result, the LED striplights will of course flicker.

- Secondly, you need to replace incompatible parts, such as LED drivers and dimmers. Dimmers and LED drivers are parts that are likely to be incompatible. In order to identify possible faults, it is important to have relatively easy access to the controls for checking them. That is, service hatches, etc. the places where the transformers are placed should be designed so that they are accessible.

- Use a power supply with a higher power rating than the amount of power required by the LED, or replace a faulty LED power supply. Please note that if the power of the led driver is insufficient, it is not possible to connect the same led striplight to several led drivers. Led transformers have different starting times, so the transformer that starts up first and has insufficient power will trip the overload protection, shut down and then restart. Then each controller continues to start and stop… The non-stop loop is ready.

- A damaged Led strip light must be replaced, either completely or for the damaged part. The Led strip should be replaced if it is bent or twisted so that the power supply is disturbed.

How to fix the flicker of an INVISIBLE LED strip?

So-called invisible flicker can appear as a faint buzzing or crackling in the light or on ballasts. Flutter can also appear through the camera lens. People are individuals, and there are differences in how flicker is perceived. Here are tips on how to get those invisible flashes under control.

- If possible, use high quality LED drivers and low voltage (12V or 24V) LED strip lights, selected with a sufficiently large load reserve.

Led driver contribute to the fact that led strip work without flicker by converting high-voltage alternating current into a constant low voltage. - PWM is the technique of switching an LED on and off very quickly at rated current. The human eye can detect the cycle as a flicker if it is not fast enough. The duty cycle, i.e. the time the LED is ON in relation to the total time of one full cycle, determines the brightness level of the LED. We have written more about PWM dimming in our article.

- Use high quality dimmers with a high refresh rate, close to 1 kHz, with the driver.

Led technology specialist

LedStore has been an expert in LED lighting and lighting design since 2010.

We have our own product design, so our products are technologically state-of-the-art.

Products have quarantee for up to 7 years.

We also carry out lighting maintenance.

We focus on temperature-controlled and high colour rendering lights, so they work brilliantly and last a long time.

We do around

500 lighting designs for our clients’ sites.

Read more here or order a lighting design

We offer a service of custom-made led strips, i.e. custom-made led strips in aluminium profile. Also installed. Did you know?

LedStore offers lighting design from 169 euros for the whole house!

Remember that we are always ready to offer our help to you along the way, by email (myynti@ledstore.fi) and by phone (045 251 4510). Feel free to share photos of your own projects on social media #ledstorefi on IG and ledstore.fi on FB. We love to see the cool things our LEDs do, and it helps to provide inspiration for those who are not sure about the power and awesomeness of LEDs. Did you know that we already have over 3500 pictures of our LED installations in our Gallery!

Photo gallery of Led lights:

Product gallery: Pictures of products in different installation locations

Indirect light: Indirect light in different spaces

Room-specific: Light in different rooms

References: complete houses that have been photographed