Summarize

- COB stands for "Chip on Board", a LED chip directly on a circuit board

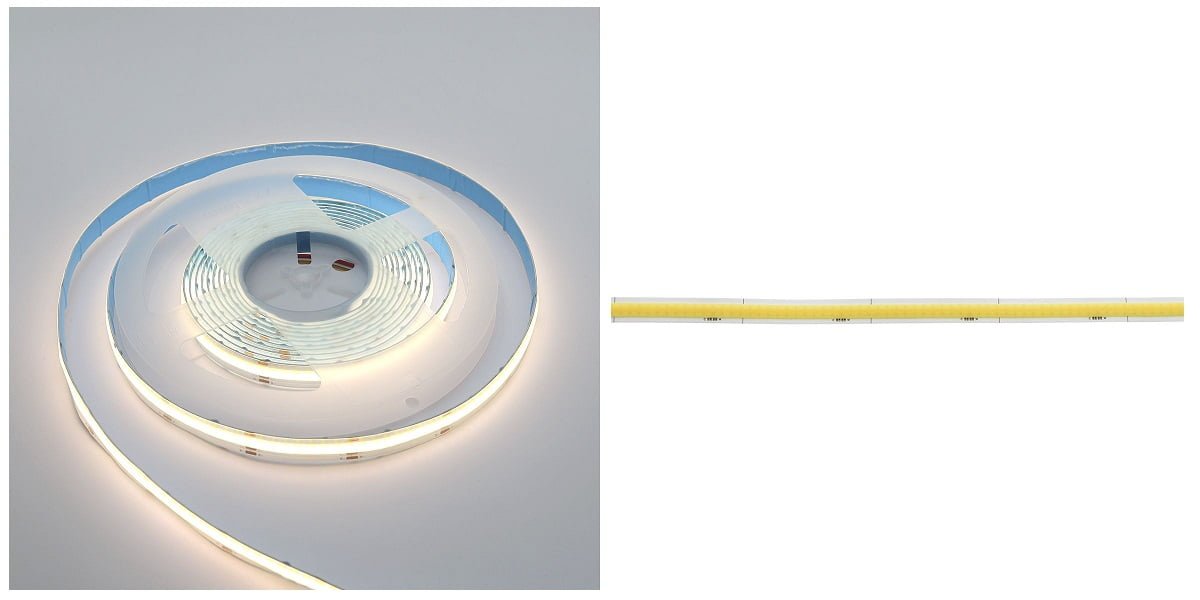

- COB-LED strip provides uniform, spotless light

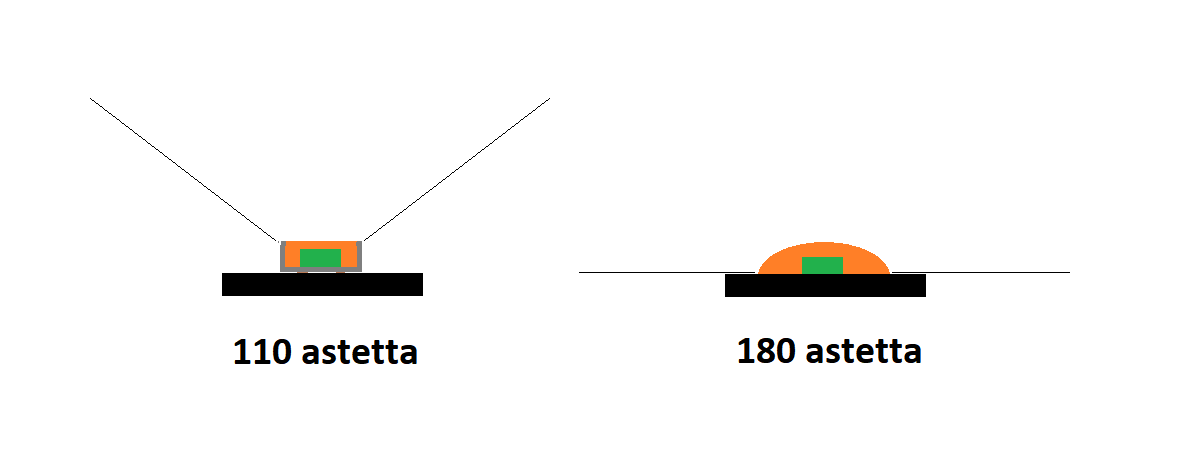

- COB-LED strip has a wider opening angle than SMD

- COB-LED strips are more flexible and easier to install

- COB-LED strips have lower luminous efficacy than SMD

Dotless led tape is the type of tape that customers have been asking for for a long time. Read more and we’ll tell you how it differs from traditional LED tape.

What is Dotless LED tape, or COB?

COB stands for Chip on Board, which means that the LED chip is packaged directly on a printed circuit board (PCB). Flexible strip lighting “Chip on Board”. COB-LEDs are essentially a simplified approach to LED design.

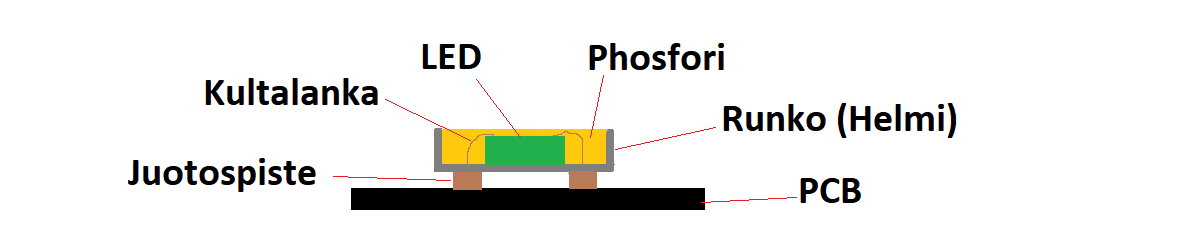

A standard SMD (Surface Mount Device) LED has an LED chip holder (bead) with the actual LED chip inside and is then covered with a phosphor coating.

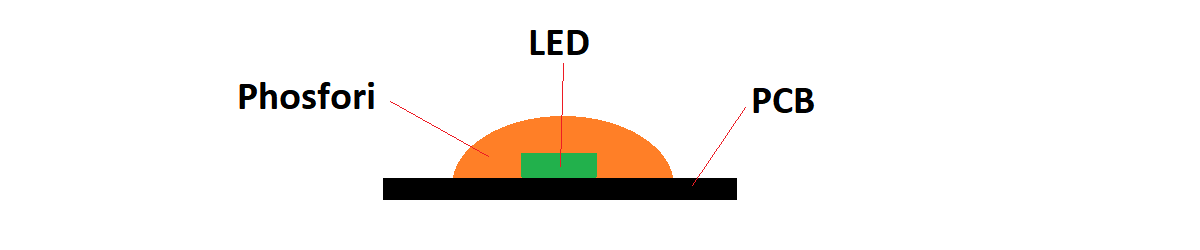

The COB-LED ribbon structure removes all excess, leaving behind the LED circuit, the yellow phosphor overlay and the junction.

COB VS SMD LED strip lighting?

- The COB led strip has an opening angle of 180 degrees, the SMD led strip has an opening angle of 110 degrees.

- COB led strip has better flexibility than SMD led strip.

- The COB led strip provides a steady, pointless light.

- COB circuit directly attached to the bottom, COB led strip has no gold wire, but SMD led strip has gold wire.

How is COB LED tape made?

- “Printing” of printed circuit boards

- Chip printer on PCB

- Printing of resistors on PCB

- “Reflow”, where at 65 degrees the components are combined

- Pouring the fluorescent mass onto the led strip

- COB led strip for the oven

- Led strip light testing and packaging.

Advantages and disadvantages of COB LED strip

Now that you know something about the technique, let’s go through the pros and cons of both techniques.

Advantages of COB LED strip lighting:

Dotless LED tape, COB led tape.

One of the biggest wishes of traditional LED strips is that there would be no dots on the LED strip. A pointless LED strip light is therefore possible with COB technology, as there are points of light up to 840 metres below a flat mass, so no visible points. The light is softer and calmer when it looks like a steady source of light rather than a pinpoint of illumination.

SMD led strips (cri 90), contain fewer of the larger led diodes. Traditionally, the number of LED light points in the so-called. the marketti led strips have 30-60 pieces per metre, so you can see very clearly each light point. There are SMD led strips with 240 LEDs per metre (LedStore EQUAL), but with these types of strip you have to take care of really good cooling, because SMD diodes produce a lot of heat. So in SMD led strip lights you can always see the dots.

With 840 LEDs per metre of COB strip, it is difficult to see individual LED dots. You can only see a single LED if you dim the strip to about 1-5% and stand next to it. This makes the COB led strip light ideal for applications where:

- The LED strip itself cannot be hidden from view (the surface of the fixture)

- The illuminated surface is less than 60cm from the LED strip (Shelves).

- Reflective surfaces, such as stone/glass, are everywhere. (dotted led ribbon)

- Those installations where you want an excellent neon effect (RGB versions).

More flexibility

COB LED strip lights are much more flexible than other traditional LED strip lights due to the small size and even distribution of the diodes. These diodes are so small and close together that no point on the strip is actually aligned, e.g. in a corner. This uniformity makes it easy to place the strips unplanned compared to SMD-LEDs, where the circuit itself hits the exact corner where it should bend. The COB led strip light is therefore more flexible in terms of installation comfort and ease of installation at every bend and angle, and there is no need to worry about breaking the led circuit at a 90 degree angle.

More stable, fewer problems

COB led strip is one long led chip directly attached to the PCB, there is no gold wire in its installation. Many of the problems with traditional SMD LED strip are due to the gold wire inside the LED “beads”. Because gold thread is thin, it breaks easily, for example from excessive heat.

The circuit design of the COB led strip uses three circuits, first in parallel, as a group, then each group and then in series to form a cut-off distance of 2.5m-10cm. Even if two LED circuits are bad at the intersection, the light will still continue forward. And because the COB led strip light has up to 840 LEDs per metre, even if 1-2 circuits don’t light up, no dark area, you can see and to the eye it’s still a score-free led strip.

In the traditional SMD led strip light, a faulty led circuit turns off the whole cutting pitch and that 5 or 10cm cutting pitch is completely dark.

Wide opening angle

A traditional SMD strip light has a beam angle of 110 degrees, while a COB strip light has a beam angle of 180 degrees. Of course, in both cases, the installation profile will affect the final result.

The weaknesses of COB led:

Difficult to maintain colour consistency

As there are no COB-LED strip loading machines on the market, all COB-LED strip manufacturers only take samples to ensure colour uniformity. So for COB LED strips, it is difficult to ensure that 100% is within the 3-phase colour tolerance. This brings us to quality control and its importance. High-quality dot-free led strip is difficult to implement.

Lower light output

The efficiency of COB LED strip lighting is currently only around 120 Lumen/Watt.

If you need higher light output, the SMD led strip light is better, as SMD reaches up to 200 Lumen/Watt. The most common ones, of course, at the 100-150Lumen level.

Lower maximum power

The maximum power of a COB LED strip is recommended to be only 15 W/m. Because the number of chips per meter is too high if the power exceeds 15 W/m. The problem is controlling the heat of the chip. Also, the life of COB LED strip is shortened in too hot conditions.

Dotless led strip light – COB led features

At this point, the pros and cons of COB light strips should be obvious, so let’s go into more detail about this type of strip. If you’re familiar with LED strip, many of these are familiar things, but COB LED strip has some differences to the traditional form.

Cut and paste

COB LED strip can be cut just like any other LED strip light. Cut only along the cut marks marked on the led strip at 25, 42, 50 mm intervals. This allows you to cut the strip to the right size or add slits to the project bag. The cut strips can be reused and are permanently joined by soldering. There are also some quick connectors on the market, but this is often not an option for size (it won’t fit in the profile) or durability.

Dimmable

The dotless LED strip is dimmable in the same way as standard SMD LED strips.

You can use Triac, PWM, 0-10V dimming power supply with COB-LED strips.

RGB, CCT and RGB+CCT dotted LED strip needs control electronics and the most popular are ZIgbee and DALI2 technologies

Colour options

White light: 3000K, 4000K and other custom colour temperatures are available.

Coloured light: RGB is available and these usually come with a white light.

Adjustable white light: CCT where the white light is freely adjustable between 2500-6500K

SUMMARY FAQ:

What is a COB-LED strip light?

COB LED tape or COB LED tape is a LED tape with LED chips attached directly to a PCB (Flexible Print Circuit Board). It is a continuous and dots-free LED strip light. So COB LED strip light to spotless LED strip light.

How do COB-LED strips work?

The LED chip is mounted directly on the PCB and covered with a layer of fluorescent material that acts as a diffuser on the chip surface. Due to their small chip size, COB LED strips have a high chip density and can exceed 800 chips per metre.

Do COB-LED strips heat up?

A standard 7.2W COB LED strip is not very hot, with a temperature of around 40 degrees Celsius.

How long does cob led tape last?

About 50 000 hours.

Are COB-LED strips brighter?

No. COB is generally not as bright as SMD LED strips. CRI98 COB LED strips have a luminous efficacy of approx. 100 Lumen/W, while SMD LED strips can have a luminous efficacy of up to 150 Lumen/W. BUT it all depends on the final product. LedStore’s SMD led strips have not been designed for maximum output, but focus on longevity and high colour rendering, always above cri 90.

Can COB LED strips be cut?

Yes, you can cut the COB LED strip at the cut mark.

Are COB-LED strips more efficient?

No, COB LED strips do not have the same luminous efficacy as SMD LED strips.

CRI98 COB LED strips usually have a luminous efficacy of 100 LM/W, while SMD LED strips can have a luminous efficacy of up to 150 LM/W.

Some other led light articles related to the topic:

Choosing transformers – Article from

Shorter article about the choice of led strip -article

Longer article on LED strip lighting: article

COB led Wikipedia article (in English)

Led lighting expert

LedStore has been an expert in led lighting since 2010. We have our own product design, so our products are technologically state-of-the-art.

We focus on light colour temperature controlled and high colour rendering index lights. We do around 500 lighting designs in a year.

We offer a service of custom-made led strips, i.e. made-to-order, easy to install led strips in profiles for everyone. Also installed.

Remember that we are always ready to offer our help to you along the way, by email (myynti@ledstore.fi) and by phone (045 251 4510). As always, feel free to share photos of your own projects on social media at ledstore.fi at Instagram and ledstore.fi at Meta. We love to see the cool things done by our LEDs, and it also helps to provide inspiration for those who are not sure about the power and awesomeness of LEDs. Did you know that we already have over 3500 pictures of our LED installations in our Gallery!

Led Lights Gallery:

Product gallery: Pictures of products in different installation locations

Indirect light: Indirect light in different spaces

Room-specific: Light in different rooms

References: Complete houses that have been photographed